Technical specification

Spring channel nut in

Description

Use

- Spring channel nut for indoor or outdoor installations.

- For direct fixing or through supports of tray systems and ladder trays systems.

Design

- Spring channel nut ready-to-install.

- The plastic spring allows the same rail nut to be used regardless of the height of the rail.

- Resistant to corrosion. (See characteristics in the declaration acc. to BS EN 61537/IEC 61537 ).

- CE marking acc. BS EN 61537 compliance.

- Immediate availability from our logistics center thanks to a complete stock of all the parts.

Advantages

- Safe, easy and quick mounting.

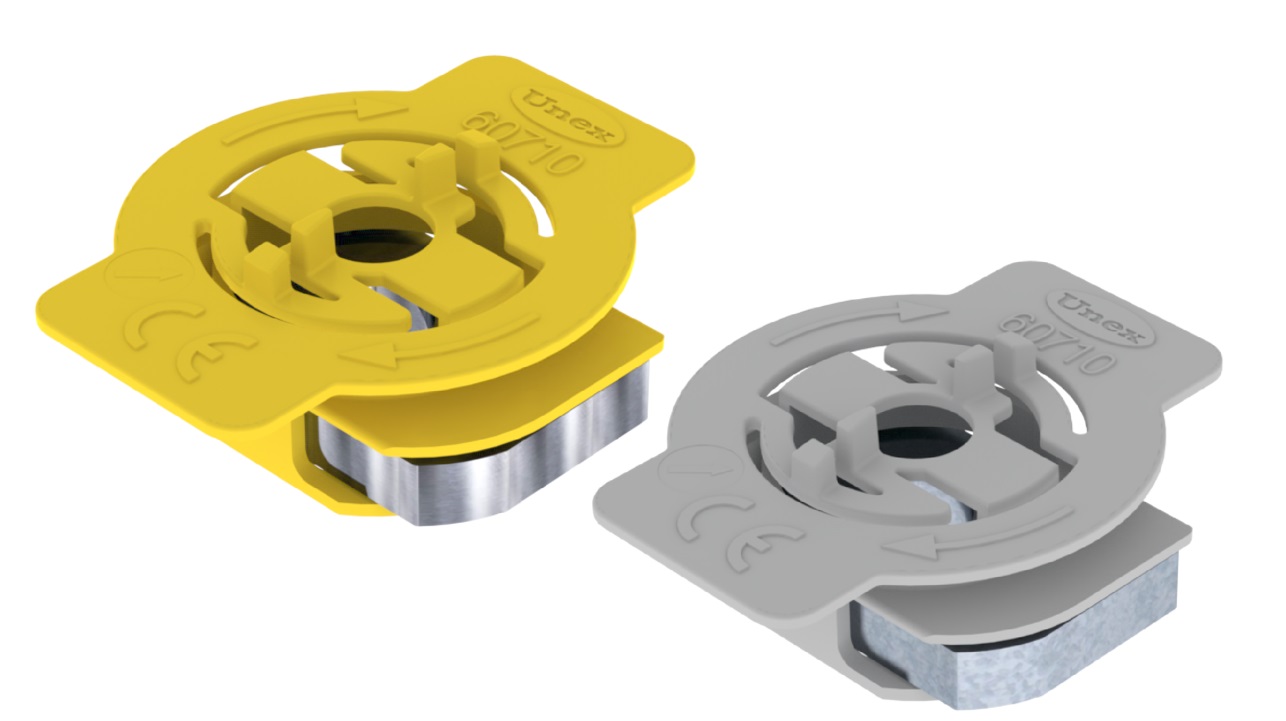

- Avalible in versions -A4 yellow capsule and -C6 grey capsule. The insulating capsule is made in U48X.

- Spring channel nut compatible with insulating strut channel 60 in U48X, rooftop support 60 in U48X and metallic struts acc. to BS 6946 standard.

- Spring channel nut compatible with cable ladder 67 rungs.

Mounting instructions

- To fulfil the characteristics defined herein, the installation must be carried out in accordance with the manufacturer`s assembly instructions provided in the main product packaging and also available on the website www.unex.net.

Product composition

- Raw material: Spring channel nut in stainless steel AISI 316 - A4 (ref. 60710-A4) . Insulating capsule in yellow U48X.

Spring channel nut in galvanized steel class 6 acc. EN 61537 (ref. 60710-C6). Insulating capsule in grey U48X. - Halogen content acc. EN 50642: Halogen free.

- Silicone contents: Without silicone (<0,01%).(1)

- RoHS II Directive compliance: Compliant .

Characteristics

|

BS EN 61537:2007 (IEC 61537:2006) International cable tray and cable ladder standard

|

|

|---|---|

|

Min./max. transport, storage, installation and application temperature

|

-20 ºC up to +90 ºC.

|

|

Electrical characteristics

|

|

|

Resistance to flame propagation s/ EN 60695-11-2:2003(3)

|

Non flame propagating system.

|

|

Coating

|

|

|

Available dimensions - Metric [mm]

|

refs. 60710-A4 y 60710-C6: M8

|

|

Flexural resistance of the strut channel nut on solid metal

|

60710-A4, 60710-C6 - 500 kg

|

|

Glow-wire test acc./ IEC 60695-2-11:2001(3)

|

Severity degree 960ºC.

|

|

Performance against corrosion (humid and saline)

|

|

|

BS 6946:1988 Specification for Metal Channel Cable Support Systems for Electrical Installations

|

|

|---|---|

|

Slip resistance - subclause. 8.1

|

Spring channel nut 60 mounted on insulating strut channel 60202-48 and 60204-48 : 18 kg (with 10 Nm torque moment)

|

|

Pull out resistance - subclause 8.2

|

Spring channel nut 60 mounted on insulating strut channel 60202-48 and 60204-48 : 76 kg (with 10 Nm torque moment)

|

Characteristics

BS EN 61537:2007 (IEC 61537:2006) International cable tray and cable ladder standard

Min./max. transport, storage, installation and application temperature:

-20 ºC up to +90 ºC.

Electrical characteristics:

- Metallic.

- Without electrical continuity.

- Conductive.

Resistance to flame propagation s/ EN 60695-11-2:2003:(3)

Non flame propagating system.

Coating:

- Ref. 60710-A4 without coating.

- Ref. 60710-C6 with metallic coating equivalent to class 6 acc. EN 61537.

Available dimensions - Metric [mm]:

refs. 60710-A4 y 60710-C6: M8

Flexural resistance of the strut channel nut on solid metal:

60710-A4, 60710-C6 - 500 kg

Glow-wire test acc./ IEC 60695-2-11:2001:(3)

Severity degree 960ºC.

Performance against corrosion (humid and saline):

- Ref. 60710-A4 - Class 9B . Stainless steel AISI 316 - A4. Insulating capsule in U48X: Inherently resistant to corrosion and therefore do not require testing.

- Ref. 60710-C6 - Class 6 . Galvanized steel equivalent to class 6 with 550 h in Sal Spray test acc. ISO 9227. Insulating capsule in U48X: Inherently resistant to corrosion and therefore do not require testing.

BS 6946:1988 Specification for Metal Channel Cable Support Systems for Electrical Installations

Slip resistance - subclause. 8.1:

Spring channel nut 60 mounted on insulating strut channel 60202-48 and 60204-48 : 18 kg (with 10 Nm torque moment)

Pull out resistance - subclause 8.2:

Spring channel nut 60 mounted on insulating strut channel 60202-48 and 60204-48 : 76 kg (with 10 Nm torque moment)

Constructive and Functional characteristics

- Safe working load: Support elements must comply with EN 61537:2006 and shall resist at least the maximum rated loads of the corresponding cable tray and cable ladder systems.

- Product packaging: Product properly packaged and clearly identified.

Compulsory regulations

|

Conformity with the demands of European Directive 2014/35/EU

|

|

|---|---|

|

CE Marking

|

Spring channel nut 60. Conformity with standard EN 61537:2007.

|

Compulsory regulations

Conformity with the demands of European Directive 2014/35/EU

CE Marking:

Spring channel nut 60. Conformity with standard EN 61537:2007.

Characteristics of U48X raw material

- Base raw material: 100% recycled halogen free thermoplastic component (4)

- Halogen contents according to EN 50642: 2018: Halogen free

- Silicone contents: <0,01% (1)

- Phthalate contents according to ASTM D2124-99:2004: <0,01% (1)

- Dielectric strength according to IEC 60243-1:2013:

18±5 kV/mm

Test sample thickness 2,0 mm. - Reaction to fire according to NF F 16-101:1998: Class F2

- UL flammability tests on plastic materials according to ANSI/UL 94: 1990:

Degree UL94: V0

Test sample thickness 3,2 mm - L.O.I. Oxygen index according to EN ISO 4589:1999:

(Concentration %) =32±3

Test sample thickness 3,2 mm - Coefficient of linear expansion: 0,07 mm/°C m. (5)

- Behaviour to chemicals exposure:

It is resistant to the majority of:

- Oils (mineral, vegetable and paraffins)

- Diluted acids

- Fatty acids

- Alcohols

- Carbonates, Phosphates, Nitrates, Sulphates and other saline solutions

- Aliphatic hydrocarbons

- Diluted hydroxides

However, it is not resistant to the majority of:

- Amines

- Ketones

- Phenols

- Aromatic hydrocarbons (5)

Notes

1. Detection limit for the analytical technique applied.

2. Except for new part numbers, which are under process of obtaining quality marks and approvals. See updated information of each part number on www.unex.net

3. Tested according to standard prescriptions of EN 61537:2007 . Equivalent to IEC 61537:2006 Cable tray and cable ladder standard.

4. Value corresponding to the last 5 years, subject to availability.

5. All features marked are based on random tests of the material in the manufacture of our products. However, they only reflect the values accepted by the raw material manufacturers, which are provided only as information and guidance.

03/05/2024